|

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

A patent is granted by a national government to protect an invention for a set number of years, usually 20. The first known UK patent was granted to John of Utynam in 1449. The patent gave John the monopoly on a method of making stained glass which was not known at that time. It was not until 1718, that a specification was required before a patent could be granted.

During the Industrial Revolution the number of patent applications increased dramatically. In 1852 the Patent Law Amendment Act created the Patent Office and greatly simplified the process of applying for a patent. It also reduced the cost as now only a single fee was payable, instead of the 7 previously required.

In 1902 the Patent Law was again changed, requiring that the Patent Officers verify that a patent was new and unique by searching through the previous 50 years patents from the date of application.

George Davidson & Co only had 12 patents granted to them up until the second world war. The three most famous are the patent for pearline (No 2641), the patent for the flower block (No 7830) and the patent for Red Cloud Glass - Ora (No 329022).

All of the English pressed glass manufacturers were granted patents for various manufacturing processes. The number, however, was dwarfed by the UK patents granted to US glass manufacturers, particularly between the two World Wars.

For more information about patents, visit the Patent Office web site at www.patent.gov.uk.

When a company or individual applied for a patent, they first sent in an application which described their invention. The Patent Office issued them with an application number, the first one each year was always No 1, and recorded the title and date received in the weekly Patent Journal. The applicant then had 10 months (7 months before 1918) to submit a complete specification. On receiving the complete specification a new number was assigned which would become the patent number if the patent was approved. If the application was not approved by the Patent Office within 18 months (10 months before 1918), then the application was lost. Applications for which no complete specification was received or was not approved were marked as Abandoned by the Patent Office.

The Patent Office only keeps copies of complete specifications, not of the original application. Thus if an application was abandoned, then only the title of the application remains.

The table below lists all of the patents applied for or granted to the Davidson Company. Details of each patent can be found by clicking on the patent number. No available specification exists for patents marked abandoned. The patent numbers are not always sequential which can cause confusion when tracing patents!

|

Application Number |

Application Date |

Patent Number |

Date Approved |

Title |

Comment |

| 3424 | 25 Aug 1879 | 3424 | 7 Mar 1880 | Improvements in the mode of finishing glass tumblers and other like articles | |

| 9400 | 25 June 1884 | Improvements in combined hand and steam steering gear | |||

| 13697 | 16 Oct 1884 | Improvements is steam steering gear and in combined hand and steam steering gear | This an the patent above were joint submissions with 'Robert Turnbull a Mechanical Engineer from Chester-le-Street' | ||

| 14030 | 2nd Nov 1886 | Improvements in the manufacture of glass tablets, sheets, slabs and the like for notices and for advertising and ornamental purposes | Application Abandoned | ||

| 2641 | 14 Feb 1889 | 2641 | 7 Dec 1889 |

Improvements in the manufacture of articles of pressed glass |

|

| 8049 | 14 May 1889 | 8049 | 15 Mar 1890 |

Improvements in pressed glass dishes and in their manufacture |

|

| 8531 | 22 May 1889 | 8531 | 29 Mar 1890 |

Improvements in the manufacture of glass shades for gas burners and such like |

|

| 20394 | 13 Dec 1890 | Improvements in the manufacture of Pressed Glass Dishes and the like | Application Abandoned | ||

| 11906 | 25 Jun 1892 | Improvement in the manufacture of glass dishes and baskets and similar articles of pressed glass. | Application Abandoned | ||

| 15216 | 7 July 1904 | Improvements in the ornamentation of glass | Application Abandoned | ||

| 12678 | 19 Jun 1905 | Improvements relating to the closing of jars and the like | Application Abandoned | ||

| 19 May 1908 | 10862 | 4 Feb 1909 | Improvements in the manufacture of pressed glass | ||

| 31 Mar 1910 | 7830 | 1 Dec 1910 | Improvements in the manufacture of glass flower blocks and the like | ||

| 25480 | 15 Nov 1911 | Method of stretching pressed glass and apparatus thereof | Application Abandoned | ||

| 23460 | 14 Oct 1912 | Apparatus for pressing glass | Application Abandoned | ||

| 12155 | 24 May 1913 | Show signs and the like | Application Abandoned | ||

| 7432 | 23 May 1917 | Manufacture of glass Lens for electric torches etc | Application Abandoned | ||

| 29300 | 28 Nov 1923 | Manufacture of moulded or pressed glass | Application Abandoned | ||

| 4575 | 11 Feb 1929 | 329022 | 12 May 1930 | Manufacture of coloured glassware | |

| 36531 | 28 Nov 1929 | 344032 | 2 March 1931 | An Improved flower holder for use with vases and like receptacles | |

| 1890 | 20 Jan 1931 | 362737 | 10 Dec 1931 | Improvements in rose or flower bowls and similar receptacles | |

| 24358 | 29 Aug 1931 | 382699 | 3 Nov 1932 | Improvements in or relating to the manufacture of glass flower blocks and the like | |

| 15013 | 29 Aug 1931 | 382902 | 3 Nov 1932 | Improvements in or relating to the manufacture of glass flower blocks and the like | |

| 8617 | 19 Mar 1935 | 430315 | 17 June 1935 | Improvements in or relating to the manufacture of stamped glass |

This was the first Davidson patent and describes a method

of finishing tumblers. The patent explains the method as follows:

The patent was issued in the name of George Davidson's son - John George Davidson. |

This patent describes the manufacture of 'pearline' glass. In the patent specification Thomas Davidson says:

“According to my invention I manufacture articles such as for example as ornamental dishes, vases, jugs, tumblers, and the like of pressed glass in such a manner that at the base they are composed of clear glass or glass of any transparent color whilst towards the top they gradually become milky and at their upper edge opaque.”

Notice how he spells color the American way! The patent goes onto explain how arsenic, lime and limespar are added to the normal glass mix and moulded in the normal way. The glass was allowed to cool for a short while, and then exposed on a punty or rod to a strong heat. This reheating produced the milky edge to the piece.

Thomas changed the relative amounts of the different ingredients between the provisional specification of February and the completed specification of December 1889 as can be seen in the table below ( I have converted from CWTs to pounds):

|

Ingredient |

February Specification |

December Specification |

| Sand | 560 lbs | 560 lbs |

| Alkali | 224 lbs | 210 lbs |

| Nitrate of soda | 28 lbs | 84 lbs |

| Phosphate of lime | 35 lbs | 70 lbs |

| Lime spar | 84 lbs | 84 lbs |

| Arsenic | 35 lbs | 35 lbs |

Thomas used this specification to produce Pearline glass in Primrose, Blue and Grey. The technique was eventually used by other companies.

|

Prior to this invention, the handles for a dish had to be applied manually, which made them more expensive to make. The technique described in this patent means that the dish can be made in a single action, thus reducing the cost. |

This patent describes how lighter and thinner glass gas burner shades can be made by first making a cylinder with a dome end in pressed glass and then expanding out the domed end and moulding it to the form required. Thomas describes the process as follows:

“To form a shade I first make in pressed glass a short cylinder with dome end and with a hole of comparatively small diameter through the centre of the dome. When taken from the mould the dome end whilst kept in a soft state by the application of heat is rotated so as to cause it to open out and expand until the hole in the centre of the dome is enlarged to a diameter greater than the opposite end of the form - whilst the enlarged end is still soft it is placed vertically on to a shape which supports it at various points around its circumference and leaves it unsupported at others so allowing these parts to droop inwards.”

The effect of supporting the shade in this way is to form flutes around the edge of the shade. The provisional specification was submitted in May 1889, and the complete specification in February 1890.

|

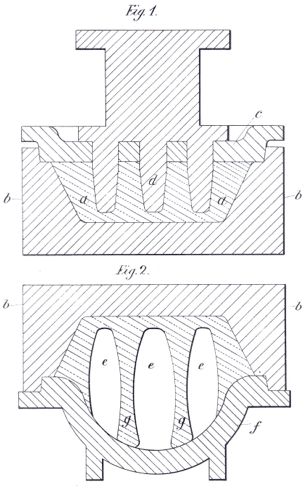

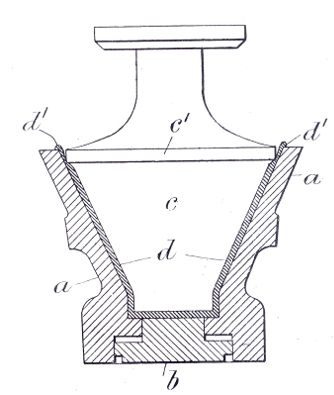

In this patent Thomas Davidson describes a mould with the top left open. Excess glass is allowed to escape from the top where it can be easily trimmed off. With a closed mould the excess glass has no where to go and so results in a thicker moulding. In Thomas' design the plunger is shaped so that it thins or indents the glass around the edge of the mould and thus makes it easier to trim off. In the diagram on the left, the plunger is marked c. The top of the plunger c' allows for the excess glass to escape and thin. In pressing the glass Thomas suggests that the plunger be brought down quickly (say 5 times) and withdrawn - the operation being more of a stamping than of a slow pressing nature. By doing this the glass in the mould is not cooled so quickly and the surface of the resulting piece is improved. |

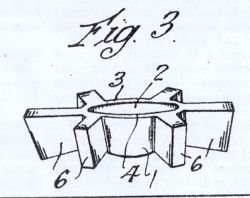

This is probably Thomas

Davidson's most famous patent after the pearline patent. It describes a

method for producing the flower block which is so familiar to all Davidson

collectors. Note, Thomas did not patent the idea of a flower block, but

patented a method of producing one. The provisional specification was

drawn up in March 1910 and the complete specification was submitted in

September 1910. The making of a flower block is a two stage

process: This is probably Thomas

Davidson's most famous patent after the pearline patent. It describes a

method for producing the flower block which is so familiar to all Davidson

collectors. Note, Thomas did not patent the idea of a flower block, but

patented a method of producing one. The provisional specification was

drawn up in March 1910 and the complete specification was submitted in

September 1910. The making of a flower block is a two stage

process:

The shapes of the two moulds can be seen in the diagram on the right. This technique allows for the flower block to have a more complicated and pleasing shape. It also allows for larger flower blocks to be made. Davidson continued to make flower blocks using this patent up until the 1960s. Two subsequent patents in 1931 improved the manufacture of flower blocks, however the basic shape remained unchanged. |

This is perhaps the most unlikely patent that was ever accepted in the 20th century. Thomas has patented the technique of painting glass! The patent was produced to protect Red Cloud glass (known as Ora). In the patent Thomas says:

“A variety of pleasing and unusual effects due to the diffusion of a dominating coloured light through translucent glass with cloud or variegated effects can readily be produced in accordance with the invention”

Thomas describes the technique as:

“According to the invention, the glass is produced with mixed, cloud or streak effects by an appropriate interfusion or mingling of two or more shades, and the article into which the said glass is shaped is coated with a backing of coloured paint or enamel For instance, a flower bowl is constructed of glass with cloud effects produced, for example, by blending in streaks or patches a limited proportion of purple or other dark coloured glass into a mass of light amber glass, and the underside of the bowl is coated by painting or spraying with a paint or enamel of any desired colour. The surface colouring may be effected with a vitreous or enamel colouring which is burnt on by spraying or painting with pigmented or dyed cellulose solutions or with ordinary oild and varnise paints”

The only known use of this technique was Red Cloud, which was Purple Cloud Glass painted on the underside or inside with a red paint. The lack of durability of the paint meant that Red Cloud was not a financial success.

The provisional specification was submitted on 11th February 1929 and the complete specification on 29th October 1929. The patent was not accepted until May of 1930.

|

Thomas describes a simple holder for flowers in vases and like articles. The holder, which could be of glass or any other material, is wheel shaped and sits inside the top of the vase, being supported by the walls of the vase. |

This patent was not taken out by Thomas Davidson but by one 'Frederic Atkinson of 49 Queen Victoria Street London EC 4, a British Subject'. However Davidson did produce a number of flower bowls which used this design. Normally the flower block or frog rests in the base of the flower bowl. In this design the flower block has three lugs on the outer edge which mate with notches moulded into the base of the flower bowl. From personal experience the problem with the design is that the frog sits too tightly in the flower bowl and can be very difficult to remove!

The two images below show the patent in action. On the right is a standard 4" frog with the three lugs visible. On the left you can see how the frog sits recessed into the bottom of the flower bowl.

It is not known who Mr Atkinson was or what his relationship was with Davidson.This design was first mentioned in the 1935 Pottery Gazette.

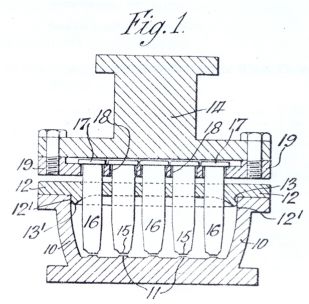

This

patent contains two improvements to the 1910 patent No 7830. The

provisional specification was submitted on 29th August 1931 and the

complete specification was submitted on 26th May 1932. This is quite a long and

complicated patent but essentially it describes a method which makes it easier

to pierce the holes in the base of the frog during manufacture.

This

patent contains two improvements to the 1910 patent No 7830. The

provisional specification was submitted on 29th August 1931 and the

complete specification was submitted on 26th May 1932. This is quite a long and

complicated patent but essentially it describes a method which makes it easier

to pierce the holes in the base of the frog during manufacture.

In the original patent, the fingers which formed the holes in the flower block did not extend to the base of the mould. This meant that there was quite a thickness of glass which had to be manually pierced to complete the holes in the flower block. This patent describes a mould which has a series of small projections in the base of the mould which align with the fingers from the top part of the mould. When the frog is made, the glass at the base of the holes is thin and so is easier to pierce.

The patent also describes some other improvements to the mould. These include a spigot-like portion which allows for excess glass to escape when the plunger is lowered and mounting the fingers, which make the holes, separate from the main plunger to avoid excess wear and to allow for movement at different temperatures.

Frogs made after the introduction of this patent bear this patent number and that of patent No 382902.

This patent, which was divided out from No 382699 describes improvements to the second part of the manufacture of the flower block. In patent 7830 it is described how the top part of the flower block is made by inverting the part formed flower block and allowing the molten glass to droop into a second mould to form the top half of the block. This patent describes two methods whereby compressed air is used to help shape the top part of the brick. The first method has the second mould perforated to allow compressed air into the mould and help form the top part of the holes. The second method does away with the second mould altogether and uses compressed air to shape the top surface of the flower brick.

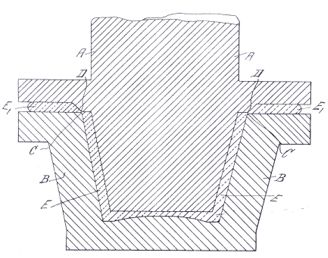

This was the final

patent which Thomas Davidson produced and was submitted in June 1935. The

patent describes an improvement to his 1908 patent (10862) for making

pressed glass with thinner sides. The plunger now has a sharp edge which

when the plunger is inserted into the open mould almost comes into contact

with a similar sharp edge of the mould. This has the effect of pinching

the excess glass and making it easier to cut when the piece is finished.

See diagram left. This was the final

patent which Thomas Davidson produced and was submitted in June 1935. The

patent describes an improvement to his 1908 patent (10862) for making

pressed glass with thinner sides. The plunger now has a sharp edge which

when the plunger is inserted into the open mould almost comes into contact

with a similar sharp edge of the mould. This has the effect of pinching

the excess glass and making it easier to cut when the piece is finished.

See diagram left.

|

|

|

|

|

"Glass

tumblers and similar articles are inverted over the the shaping block

A, brought up into position by a hinged lever working through an

inverted L slot a in the table B1. A shaping ring C, Figure 5 and 6,

is then passed from the bottom to the top of the tumbler, the lever is

then lowered, and the tumbler is removed by the annular tray b. For

sugar basins and other articles with feet, the apparatus is the same,

with the addition of a vertical rod carrying a sliding horizontal rod

and disc which can be brought over the foot of the sugar basin so as

to keep it in position during the shaping; also the finished basin is

removed by pliers instead of the annular tray."

"Glass

tumblers and similar articles are inverted over the the shaping block

A, brought up into position by a hinged lever working through an

inverted L slot a in the table B1. A shaping ring C, Figure 5 and 6,

is then passed from the bottom to the top of the tumbler, the lever is

then lowered, and the tumbler is removed by the annular tray b. For

sugar basins and other articles with feet, the apparatus is the same,

with the addition of a vertical rod carrying a sliding horizontal rod

and disc which can be brought over the foot of the sugar basin so as

to keep it in position during the shaping; also the finished basin is

removed by pliers instead of the annular tray." This patent was

first applied for in May 1889, but it was not until February the following

year that the complete specification was received. The patent describes how to

make a glass dish (Fig 6 right) with a central raised division and with a

loop handle standing on top of the division. This dish is made from a

mould which consists of two or more parts. As Thomas describes the

process:

This patent was

first applied for in May 1889, but it was not until February the following

year that the complete specification was received. The patent describes how to

make a glass dish (Fig 6 right) with a central raised division and with a

loop handle standing on top of the division. This dish is made from a

mould which consists of two or more parts. As Thomas describes the

process:

This patent describes a

method of producing thinner pressed glass with an improved surface. The

provisional specification was dated 19th May 1908 and the complete

specification was accepted on 4th February 1909.

This patent describes a

method of producing thinner pressed glass with an improved surface. The

provisional specification was dated 19th May 1908 and the complete

specification was accepted on 4th February 1909.

The simple patent took over a year to be

granted. The provisional specification was submitted on the 27th November

1929 and the complete specification on the 11th August 1930. The patent

was finally granted in March 1931.

The simple patent took over a year to be

granted. The provisional specification was submitted on the 27th November

1929 and the complete specification on the 11th August 1930. The patent

was finally granted in March 1931.