|

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

The 1861 Ordinance Survey map of the Teams area of Gateshead shows an essentially rural area with few houses and virtually no industry except for some small brickworks. This land formed part of the Redheugh Estate and was owned by Henry William Askew. The only sign that this was to become a major industrial area was the presence of the North-Eastern Railway line which ran past the Teams river towards the River Tyne. Throughout the mid and late 1800s parcels of this land were sold off for housing and industry. The 1897 Ordinance Survey map shows a completely different landscape. The rural landscape had been taken over by industrial sites and houses for the workers. The various brickworks had expanded and large quarries appear where the clay was dug to make the bricks. Davidson's Glassworks, in the bend of the Teams known as the Gut, is a large industrial site with it's own quays on the Teams and railway lines into the factory.

Although the Davidson Glass Company started in 1867, it was not until the 23rd October 1868 that Davidson bought the site of the Teams Glassworks from the Redheugh Estate. Whether the factory was on this site or elsewhere prior to this purchase is unknown. George Davidson paid £600 for a parcel of land 'bounded by the River Team to the north, east and west and partly by the North Eastern Railway to the south'. In addition George paid a tithe rent-charge of £1 8s 6d per year. Part of this money was to pay for a public road.

The glassworks was built on this Greenfield site and by 1889 the Davidson factory was described as follows in a book entitled 'Tyneside Industries' published by the Historical Publishing Company:

'The premises constituting the Teams Glass are at once extensive and compact, and comprise offices, a large packing shed, commodious warehouse for the storage of finished goods, four 8-pot furnaces and a mould making department, very complete in all respects and considerably larger than is usually the case. There is also an extensive building in addition to these, part of which is used as a sand warehouse, part as a shop for the mixing of glass forming ingredients and part as a pot loft. This building is about 150 feet long by 40 feet wide. Throughout the works the floors are nearly all laid in cement, preventing damp and the risk of fire, and all buildings are reasonably airy and well ventilated. A special feature in connection with these works consists of the Lehrs for annealing glass. These are supposed to be unsurpassed by any in existence and such a fact is obviously of very great importance, the proper tempering of glass has so much to do with its durability. The works cover a large area of ground and have excellent quay and railway accommodation on each side of the works for the delivery of raw material and of coals, and also for loading, being situated on a sort of peninsular of the river Teams.'

The glassworks quickly developed from the first furnace. As Davidson moved from manufacturing only paraffin lamp chimneys to small bottles and wine glasses, coal-fired Lehrs were added. After the first 10 years of production the glassworks had four furnaces in operation. These were circular in shape and had a small brick cone. They could hold six to eight covered pots, each pot holding between 6-7 cwts of glass. All of the furnaces were directly coal fired.

In 1881 a serious fire destroyed most of the warehouses and processing departments. Although the furnaces were undamaged, production was stopped between January 1881 and April 1881.

Over time the size, capacity and design of the furnaces changed so that more glass could be produced in an even more efficient manner. The original furnaces were, at some point in the 1880s, replaced by Boetious furnaces an these were in operation until as late as 1926 when the last was replaced by the Stein type of recuperative furnace.

In 1887 the factory require more land, and a small parcel of land was purchased from the neighbouring Redheugh Iron and Steel works. Davidson were to later find out that they had not bought all of the land they thought they had.

Towards the end of the 19th century, larger and larger pots to hold molten glass were required. As these could not be sourced from their existing suppliers, the Davidson factory started making their own. This was a very skilled craft, and the techniques for manufacture were often passed down from father to son. Indeed the family of one of Davidson's pot makers had been following the trade since about 1750. The pot was made by adding layer after layer of clay and as each layer was added it was shaped by hand. Not only great skill was required, but infinite patience as well.

The first recorded planning application in the Newcastle archives for the glassworks was in 1903 when a plan was submitted for increasing the office space. The next plan submitted was not until 1931 when Davidson applied for permission to add a 500 gallon petrol storage tank to the site.

In the early years of the 20th Century, there many changes inside the factory. Just before the First World War the glory holes were converted to fuel oil from coal. Annealing methods had also been improved with the installation of coke-fired pan-type lehrs. These in turn were replaced in 1931 by electric lehrs. Between 1921 and 1926 the Boetious type furnaces were replaced with Stein furnaces. These required building a gas produced, by 1927 two of each had been built. In 1936 the furnaces were converted to use Town Gas.

In 1935 the neighbouring Redheugh Iron and Steel works ran into financial problems and Davidson took the opportunity of purchasing 1,575 sq yards of land from the receivers for £160. Included in this purchase were 3 plots of land which Davidson had thought their owned, but had been specifically excluded when they purchased some land from Reheugh in April 1887!

Just prior to the Second World War, many changes were planned to the glassworks. Modifications to the existing offices were made as well as a a new paper store, meter house, garages and another petrol storage tank were built.

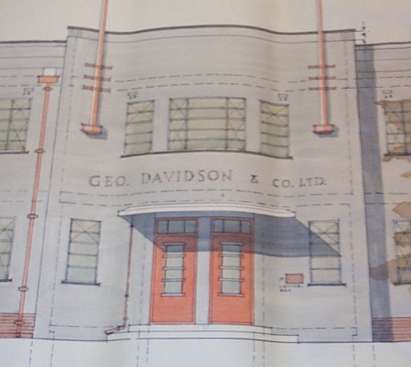

In 1939 plans were approved for new offices for the Teams Glassworks. The offices were located at the entrance to the site and be built in the Art Deco style. The pictures below show the front elevation of the offices and a close-up view of the entrance.

(By permission of the Chief Archivist, Tyne and Wear Archives,

Acc No T311/1939/261)

This two storey building was designed with many classic Art Deco features. Of particular note are the wide metal framed windows and the interior hallways which were designed to have terrazzo floors. Flanking the first floor showroom, which was located above the entrance hall, are two flag poles. The inside accommodation consisted of:

Basement:

Strong room/ARP Shelter

Ground Floor:

General Office

Mr Gellow's office (which had a glass partition to the typists room)

Mr Balman's office

Typists room

Room for Drawings and Instruments

Directors' Cloakroom

First Floor:

Director's (Mr Frazer) office with Oak Parquet flooring

Mrs Robb's office

Showroom

Mr Fullerton's office

Office for Typists

Store room

Cloakroom (Men and Woman)

Even in 1939, when the plans were approved, there was concern about enemy action as the strong room doubled as an ARP shelter.

These offices are all that is left of the Davidson Glassworks.

Fortunately the glassworks were not bombed during the war, and in 1943 a staff canteen was built. The next change at the factory was in 1950 when an extension to the Lehr building was allowed. This was followed in the following year with a plan to add a new 3 ton glass furnace. More extensions were improved in 1954 followed by an 'Amendment to sanitary arrangements' in 1955 and a new female lavatories in 1956. A new form store was added in 1963.

Following the takeover by Abrahams in 1966, a large addition to the factory was made, which almost doubled the size of the existing buildings. This addition included a plating area (Abrahams made chrome fittings for industrial and domestic wares). This work was followed in 1968 by a plan for another extension and repairs to part of the roof which was damaged by fire.

In 1969, Davidson installed a Random Auto Glydol Plating Plant. This caused considerable problems during commissioning. Davidson now had the only fully integrated glass and metal production facility in Europe. Sadly this investment was not sufficient to ensure the long term future of the company.

Following the closure of the Davidson glassworks in 1987, most of the buildings were pulled down. All that remains are the 1939 offices and the shell of an old brick building at the far end of the site. The site now consists of concrete hard standing and modern warehousing for a car components distributor. Next to the Davidson site the Redheugh Iron and Steel works still stands, but the old Rope works has long gone.

|

|

|

|